Renewable energy source - cogeneration unit Turbogenerator HAESBIO 200

EL-INSTA ENERGO s.r.o introduces a new biomass cogeneration unit. Compared to other units it is characterized by significantly higher efficiency, higher performance and low failure rate. And all with a "made in the Czech Republic" sign.

Our company EL-INSTA ENERGO s.r.o. has been supplying high-voltage power supplies for 25 years. equipment for el. energy and consumer, engineering and quality assurance. energy. We are also engaged in renewable energy sources - we have 11 MW in photovoltaics and we are also involved in combined heat and power (CHP).

We were inspired by the equipment of the English company TALBOT, which uses a turbocharger as a gas turbine, where natural gas is burned in the pressure section between the compressor and the turbine. A turbine without a gearbox drives a high frequency generator. The generator output is rectified and converted to a network frequency via the inverter. However, the device is more defective and operates only with low power, in the order of tens of kW) and with ORC systems. ORC work with low efficiency, max. 18%, have a more complex system, with at least one evaporator and one water condenser and three working media - air, silicone oil, water / steam. That is why we have decided to produce a similar device and it is simpler and working with much higher power - in the order of hundreds of kW and with greater efficiency. In cooperation with Ing. Kundera from PBS ENERGO and with doc. Ing. We have developed a cogeneration turbo-generator unit, which can operate with power up to 500 kW.

Our solution is unique in that the working medium is only air - flue gas (in the boiler and in the air / air heat exchanger) and there is only clean air on the turbine, ie. without ecological load and further without high pressure (working pressure 2 to 3 bar). For this reason, it is possible to use the energy-efficient waste heat directly, for example, for a dryer or paint shop without additional heat exchanger.

The main benefit is the anticipated greatest efficiency (up to 20%) of all previously known small el. energy and heat. A great advantage is that compared to piston combustion engines (diselgenerators, gas generators), the system is very durable, reliable and almost trouble-free, so it is able to operate in continuous year-round operation (7,500 hours / year). It is a low-maintenance, affordable, combined heat and power product.

The turbo generator itself uses the energy of waste flue gas or high temperature air 390 - 640 ° C, pressure 2-3 bars, flow rate 2 m3 / s.

The market perspective of the HAESBIO energy block is based on the long-term and sustained trend of increasing the share of biomass and waste disposal as the most important renewable source in electricity and heat production. Therefore, the concept of the unit is focused on biomass - wood chips, waste wood and agricultural production, pellets from the mentioned raw materials; (for wood chips and pellets, the advantage of loading automation).

As the output is clean air, the TG unit is suitable for direct use for industrial plants, farms - drying of agricultural crops, woodworking companies - wood drying, sawdust; paint shops, pellet production, urban heating plants; island systems with their own production of electricity and heat, cold, air conditioning. The TG also meets the requirements for low noise and emissions according to EN 303-5 (EURO 5) - so it can also be installed in urban areas.

Because the turbine can also burn so-called dirty gas, the most promising is currently the use of HAESBIO 200 in cogeneration of electricity and heat from affordable fuel at landfill sites. In conjunction with a municipal waste gasifier, it can also work as an island system in the landfill - to dispose of waste and to produce el. energy. For this purpose, the gasifier will be supplied by NWT, a.s. Zlín, which cooperates with the Research Energy Center at VŠB-TU Ostrava.

It is also used in technologies where unused waste heat is available (aluminum plants, foundries, steel mills) from which electricity can be generated when connected to a turbo-generator.

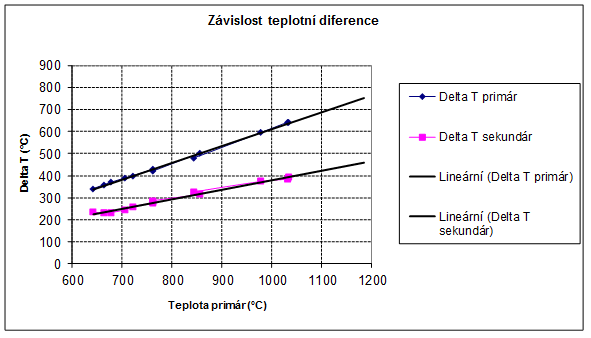

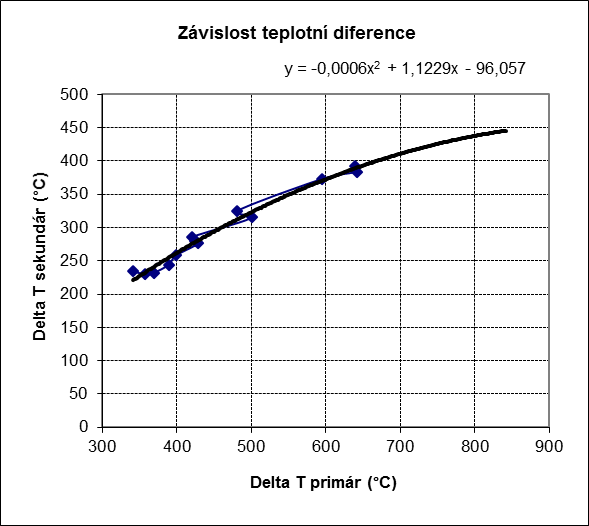

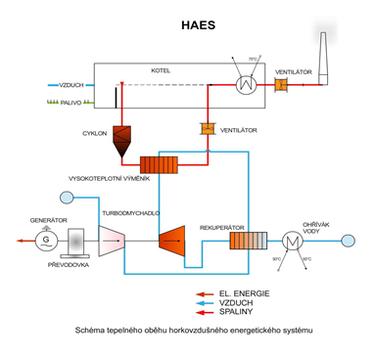

Wood chips are burned in the boiler and flue gas is produced at about 1000 ° C. The flue gas passes through the cyclone separator to the hot air exchanger into the primary section of the refractory tubes, transferring the heat to the pure secondary air that flows rotationally around the tubes below the exchanger shell. The cooled flue gas is led back to the rear of the boiler, where it still heats the water in the recuperator and then exits the chimney.

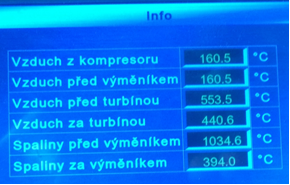

The clean secondary air was previously sucked through the filter into the compressor, compressed to 2-3 bars, flowing through 2m3, and passed through the recuperator at a temperature of about 160 ° C to the aforementioned secondary part of the heat exchanger and heated up to 480 ° C at 550 to 640 ° C. The heated and compressed air is fed to the high pressure turbine, which is rotated at 30,000 rpm, while cooling and at the outlet of the turbine the air is still at 390 ° C to 450 ° C. Thus, for the work of the turbine at PN, the temperature gradient at the turbine of 130 ° C to 190 ° C is sufficient. Since the output of the turbine is clean hot air, which still has a large heat energy, it is suitable for direct use for dryers, paint shops and possibly for air conditioning systems, and can also be used for heating.

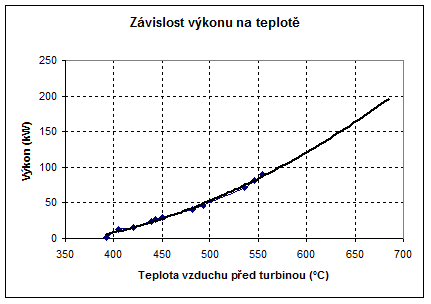

The turbine is on a common shaft with a driven compressor and on the other side of the shaft is connected via a clutch and a gearbox with el. generator, which then produces el. energy. Shaft slides on oil film; pressurized oil is prepared in the lubrication system. To drive the generator, the gearbox speed is reduced 1:10 to 3000 rpm. Generator produces el. energy for the user's own consumption or may be phased to the power. sewing. Turning set time to rated power is up to 5 min. Also positive is the fact that the turbine reacts very quickly to a change in temperature or air pressure, and the power of the generator is linearly dependent on the flue gas temperature, or secondary clean air, in a large characteristic curve.

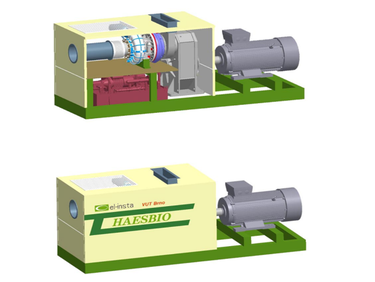

At present, we have produced one complete prototype, which is located at the ATOMA plant in Sudoměřice nad Moravou, where a trial operation in connection with a wood chip boiler was also successfully carried out. This prototype already has its new owner. It is an agricultural farm on the Portuguese island of Madeira, where TG will supply 160 kWel and 800 kWt of agricultural production and greenhouses.

Our development department is constantly working to improve this project.

Heat section:

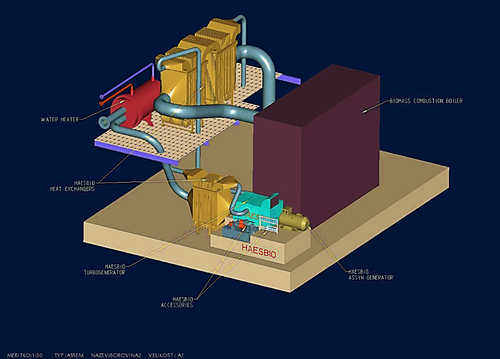

Heat source: biomass-fired boiler (fully automatic, ATOMA - thermal technology)

Chip stack with feeder.

An alternative to the heat source may be a pellet boiler or a waste gasifier, biomass, etc.

Flue gas / air heat exchanger (manufacturer ATOMA - thermal technology)

Air / air heat exchanger

Water heater

Alternatively, an outlet air chimney

Turboset: compressor + turbine (manufacturer PBS Turbo Velká Bíteš):

El. accessories:

Other accessories:

System characteristics:

Main technical and economic parameters:

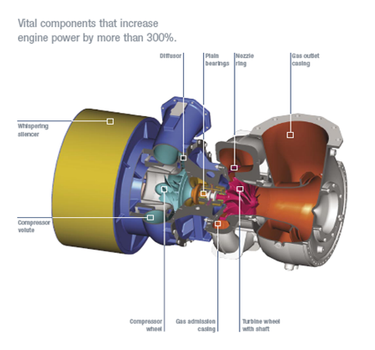

The description of the system components is the MAN TCR gas turbine Principal scheme

Separate municipal waste gasifier, plastics, tires, biomass, etc. (supplied by NWT a.s., Zlín)

Here we see the greatest use of TG, because unlike other cogeneration units where clean gas is burned, this unit can burn so-called dirty gas from gasified waste. NWT cooperates on the development of the gasifier with the Research Energy Center (VEC) at the Technical University of Ostrava.